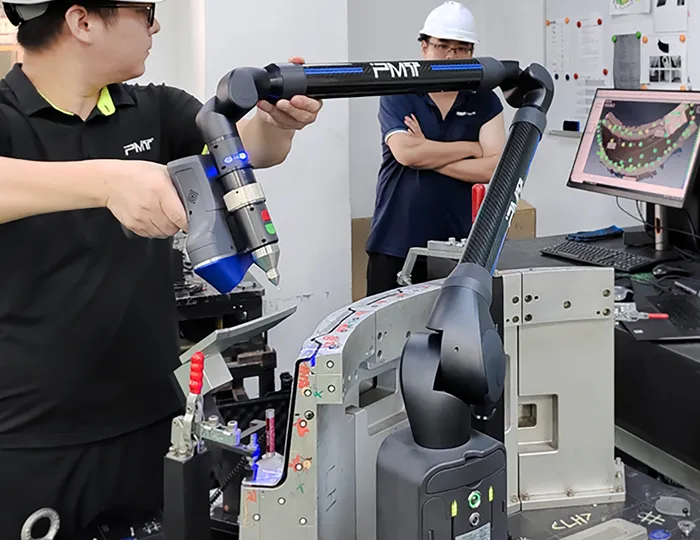

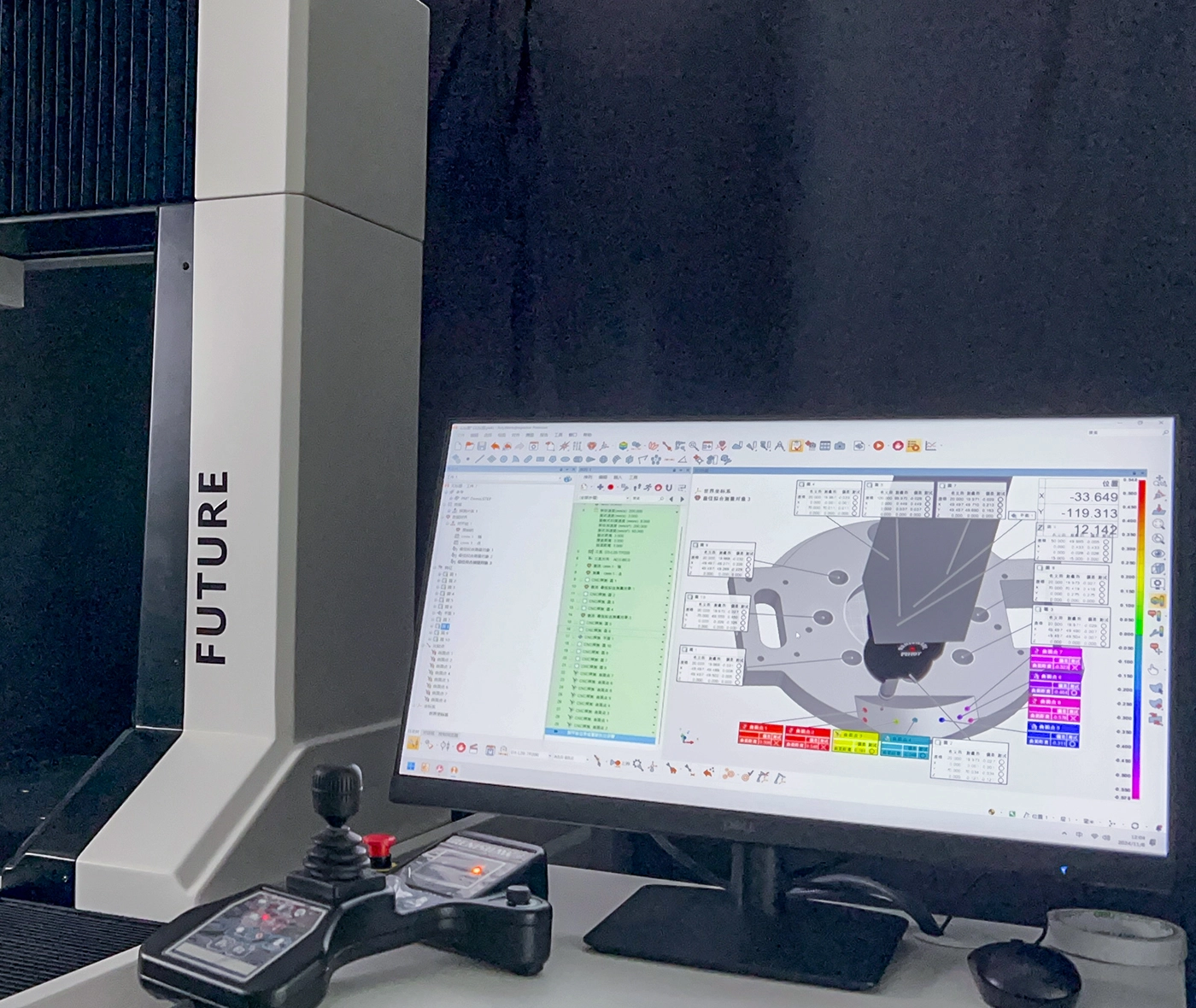

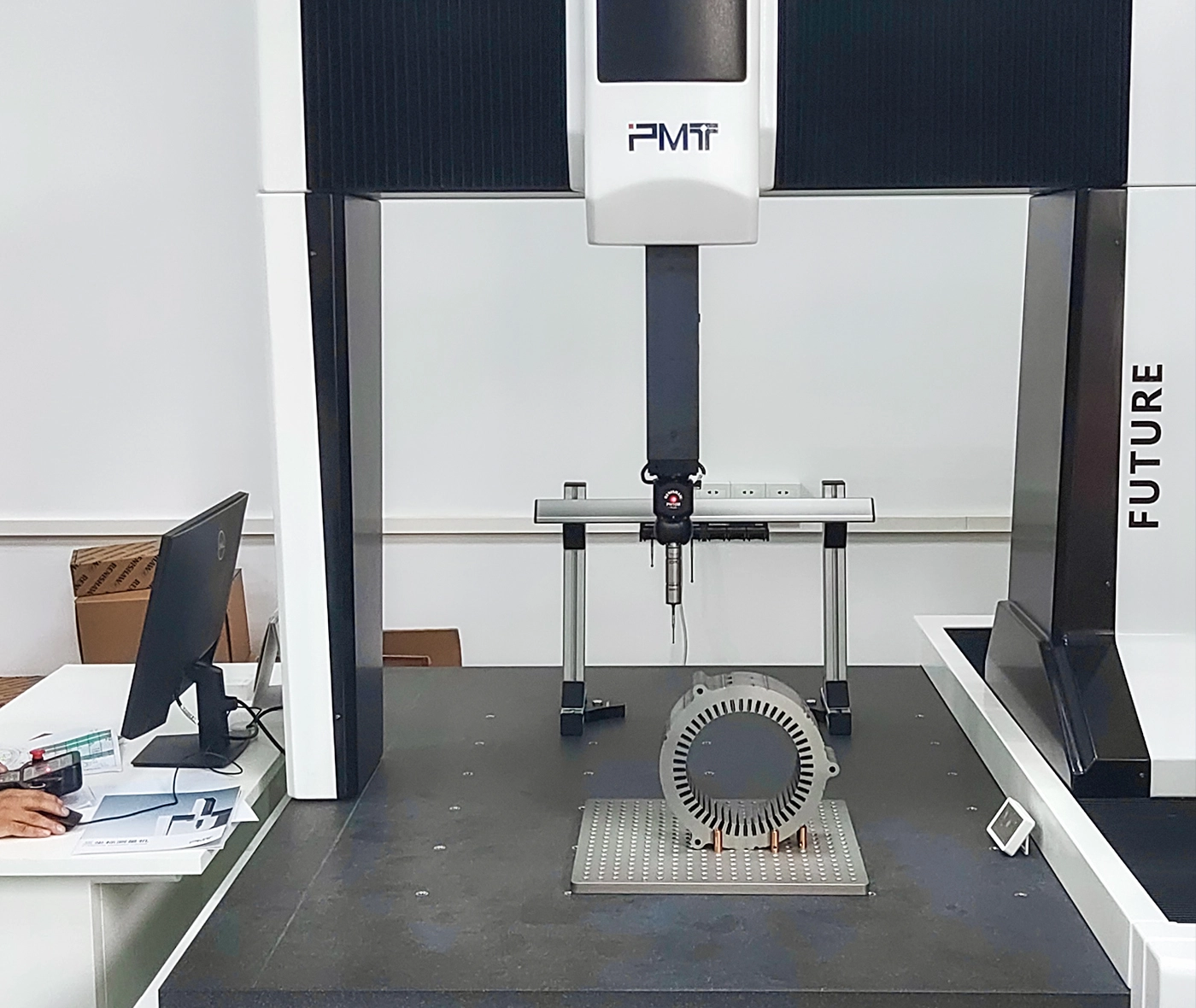

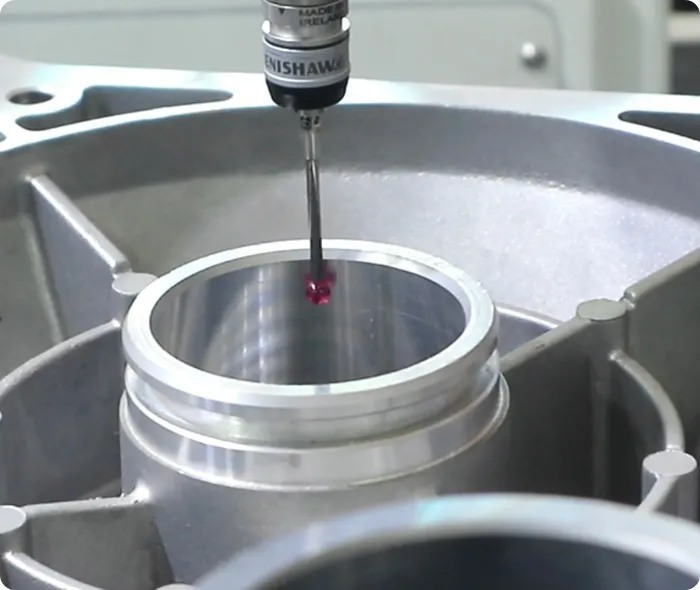

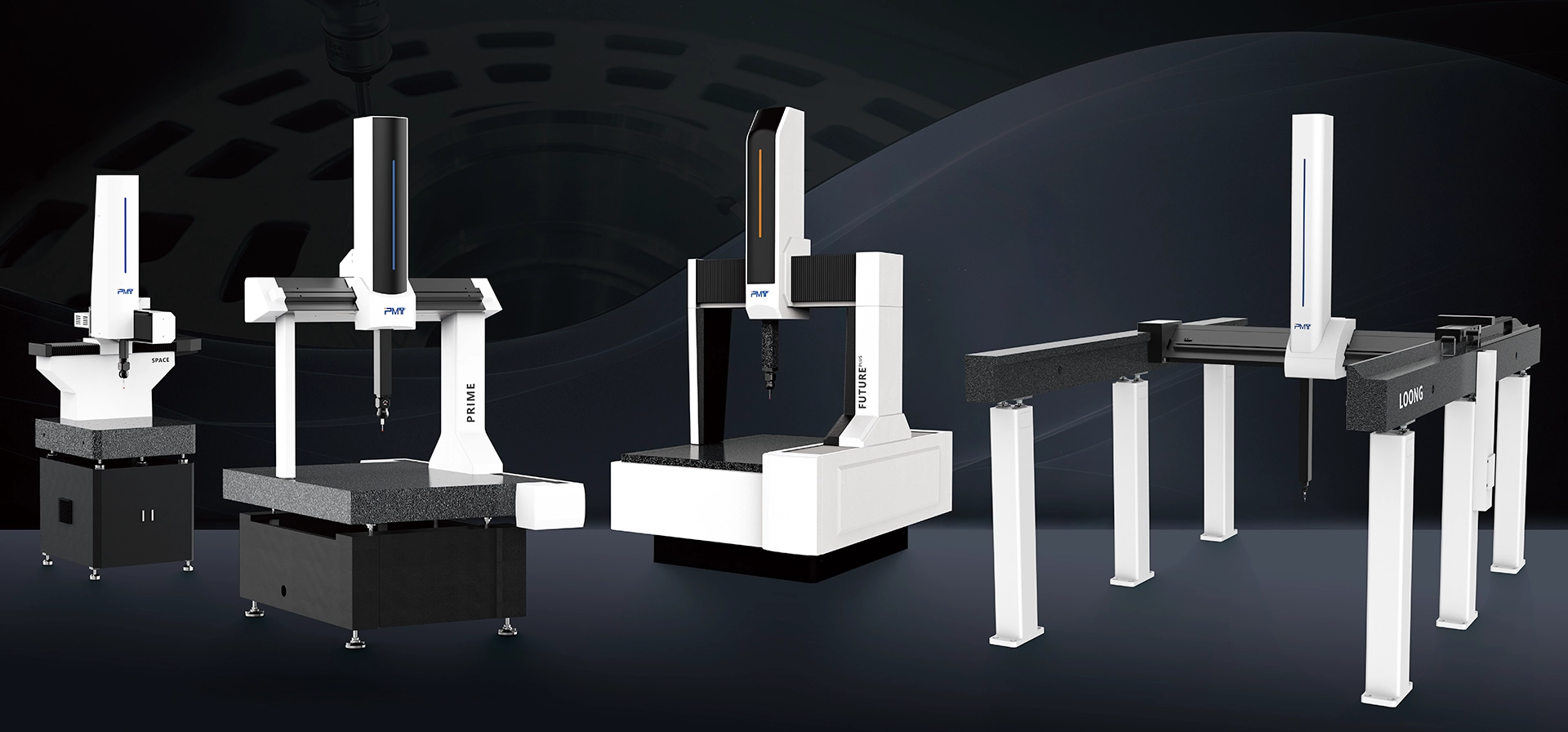

In order to meet the design and factory requirements, the automobile fixture needs to go through the verification by CMM, and issue the relevant adjustment quantity and accuracy report. In particular, the welding fixture of automobile sheet metal generally has the characteristics of large detection range, dense tooling, and complex use environment. The application of PMT measuring arm in automobile fixture inspection significantly improves the detection efficiency, adapts to the complex environment, and is an important means to adjust the fixture accuracy and maintain the production accuracy of the process.

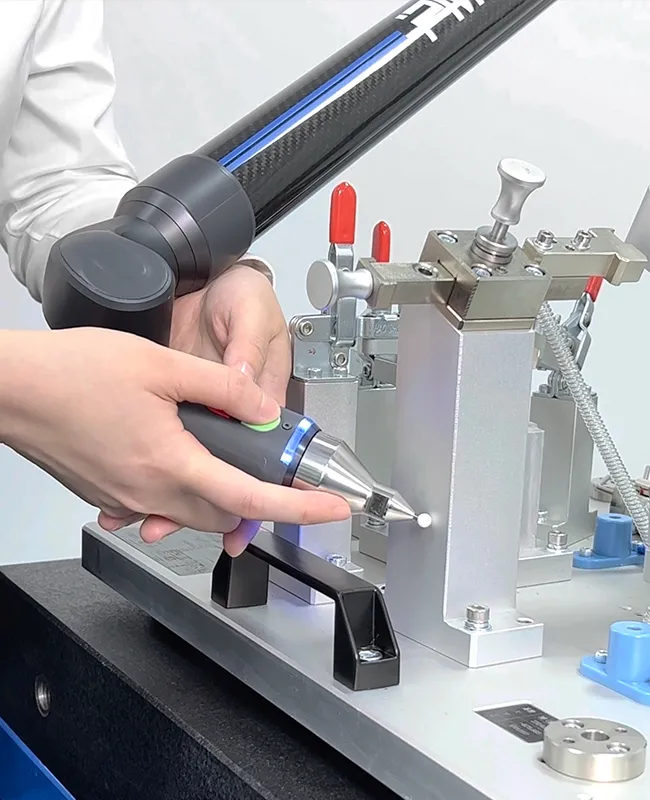

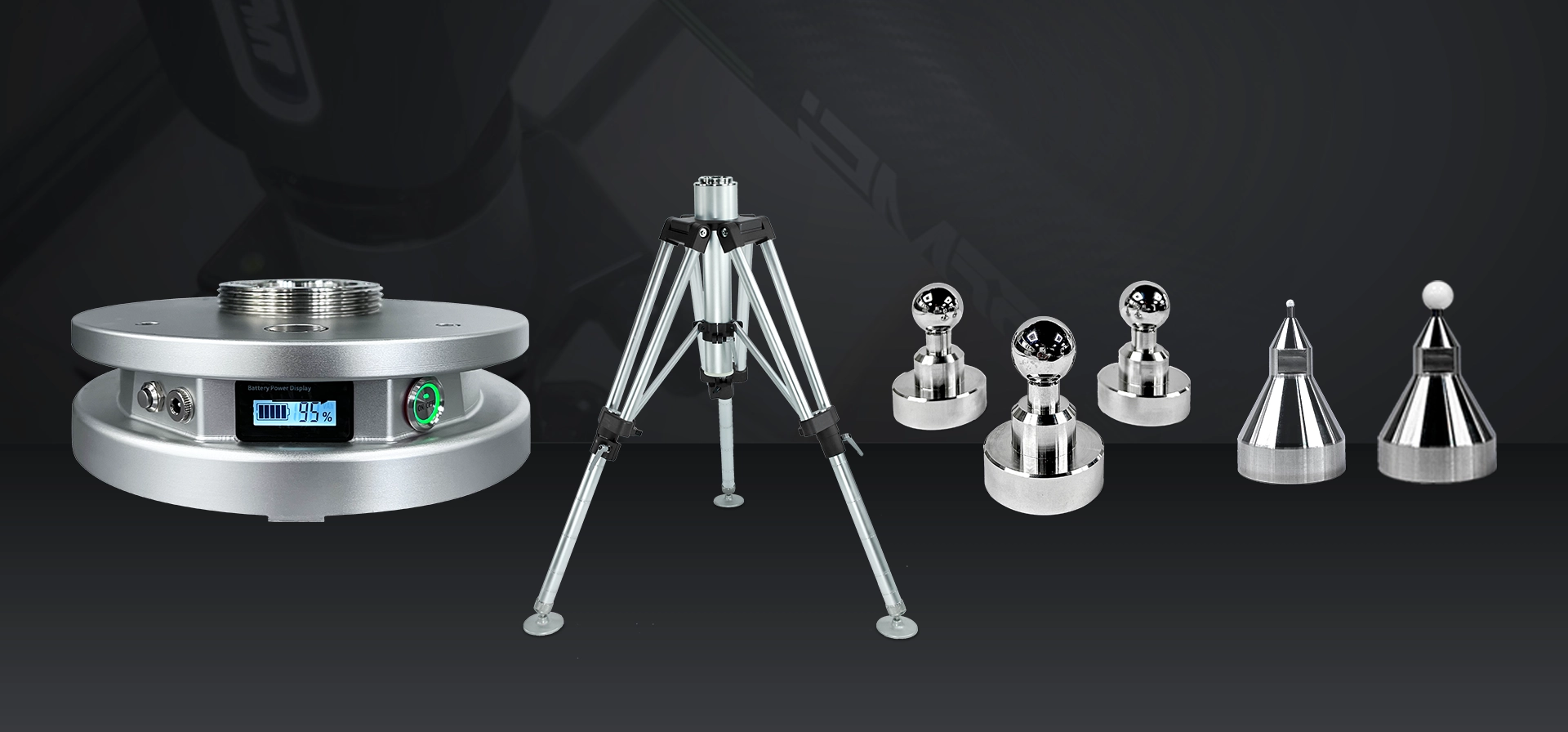

- PMT measuring arm uses a built-in balance and 360° infinite rotation mechanical structure, which is simple and tiny in appearance, making the measurement more flexible. The installation and measurement while swinging the arm body are less interfered during the tooling process.

- The overall circuit is highly integrated, low power consumption, and the dual batteries can ensure 12 hours of working time, so as to ensure uninterrupted work on the site with tight electricity.

- With a temperature compensation system, PMT portable arm is able to respond to large temperature difference when measuring at shop floor, providing a guarantee for data stability.