In today’s manufacturing world, accuracy defines competitiveness. As product standards become more demanding and tolerance levels get smaller, companies across the globe are looking for reliable ways to ensure consistent quality. Precision measurement is no longer an optional process—it is a core foundation for smart manufacturing.

Chengxin Machinery: From Traditional Production to Intelligent Manufacturing

Located in Guangxi, China, Chengxin Machinery (formerly a state-owned enterprise) has been part of the Yuchai Group for over 60 years. The company specializes in high-precision components such as diesel engine connecting rods, gear covers, and key internal combustion parts.

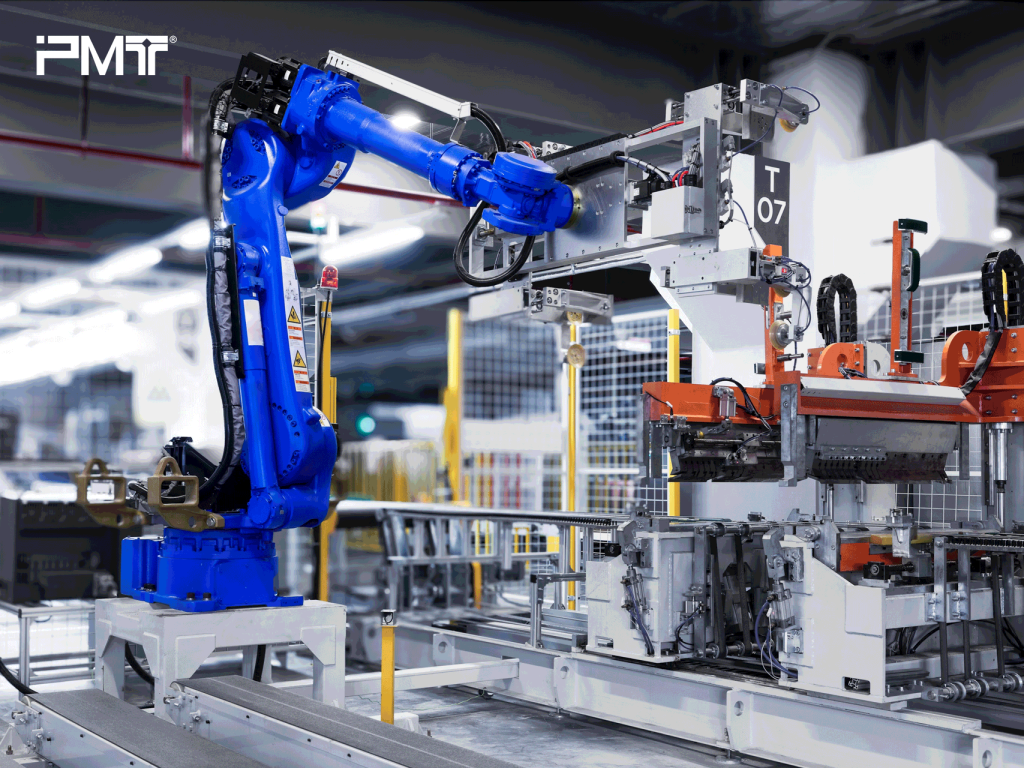

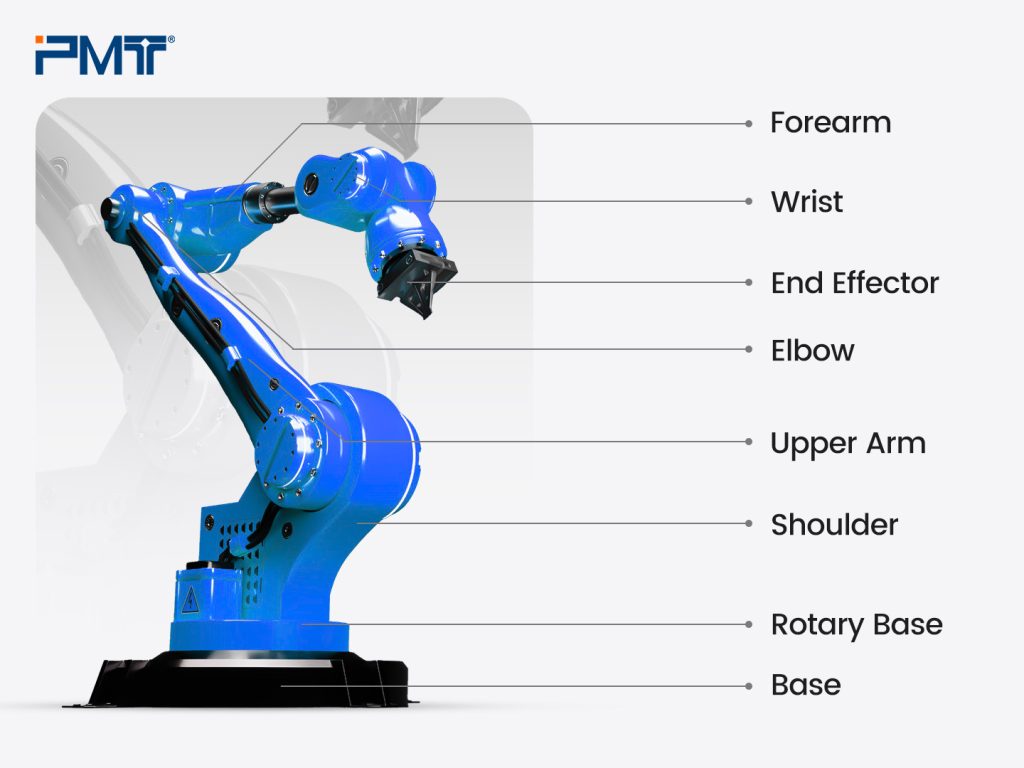

In recent years, Chengxin has moved beyond traditional machining and entered the field of industrial robot integration, marking a major step toward intelligent manufacturing. However, with this transformation came a familiar challenge—how to maintain high quality while increasing efficiency and controlling costs.

The Challenge: Assembly Misalignment in Robotic Components

During the assembly of robotic parts, Chengxin’s inspection team discovered a recurring issue: some of the robot’s second-axis rotating bases (turntables) were difficult to align with positioning pins, and a few connecting bolts tended to loosen after installation.

To find the root cause, the team needed to verify whether key machining dimensions of the second-axis turntable were within tolerance limits. Precise measurement was essential to understand the misalignment and optimize the process.

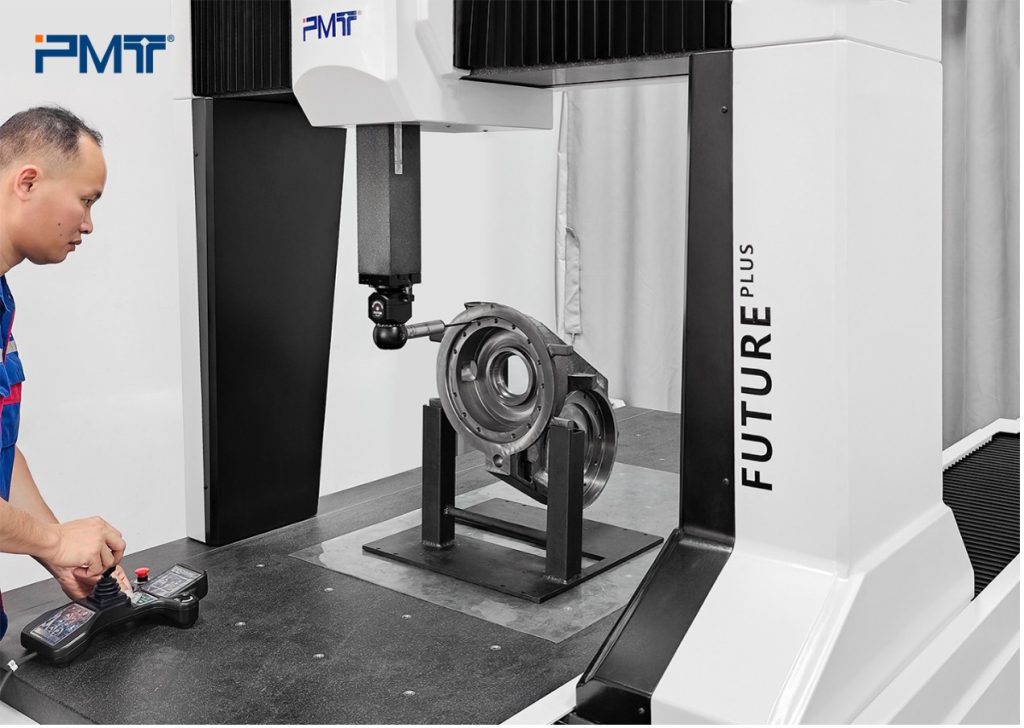

It became clear that a highly accurate, stable, and efficient coordinate measuring machine (CMM) was required. After thorough evaluation, Chengxin decided to acquire one through a public tender.

Why Chengxin Chose PMT

Among several international and domestic competitors, PMT’s FUTURE PLUS 1587 CMM stood out after a detailed technical comparison and on-site testing. The decision was driven by four key strengths:

1. Higher and More Stable Accuracy

The FUTURE PLUS series uses advanced photoelectric scales and a precision transmission system to achieve micron-level accuracy. It met Chengxin’s strict requirements, including:

- Measurement accuracy within 2.1 + 3.3L/1000 μm

- Scanning error less than 3.5 μm

- GN evaluation and offline programming support

2. Excellent Cost Performance

PMT’s independently developed precision assembly technology delivers European-level quality at a highly competitive price, offering the perfect balance between performance and investment.

3.Reliable After-Sales Service

With a strong service network and rapid response capability, PMT ensures that Chengxin receives timely technical support and continuous operation stability throughout the product’s lifecycle.

4.Secure and Controllable Technology

Unlike many imported systems, PMT provides domestically developed measurement software and control systems, ensuring full data security and system independence—an important factor for companies with global strategies.

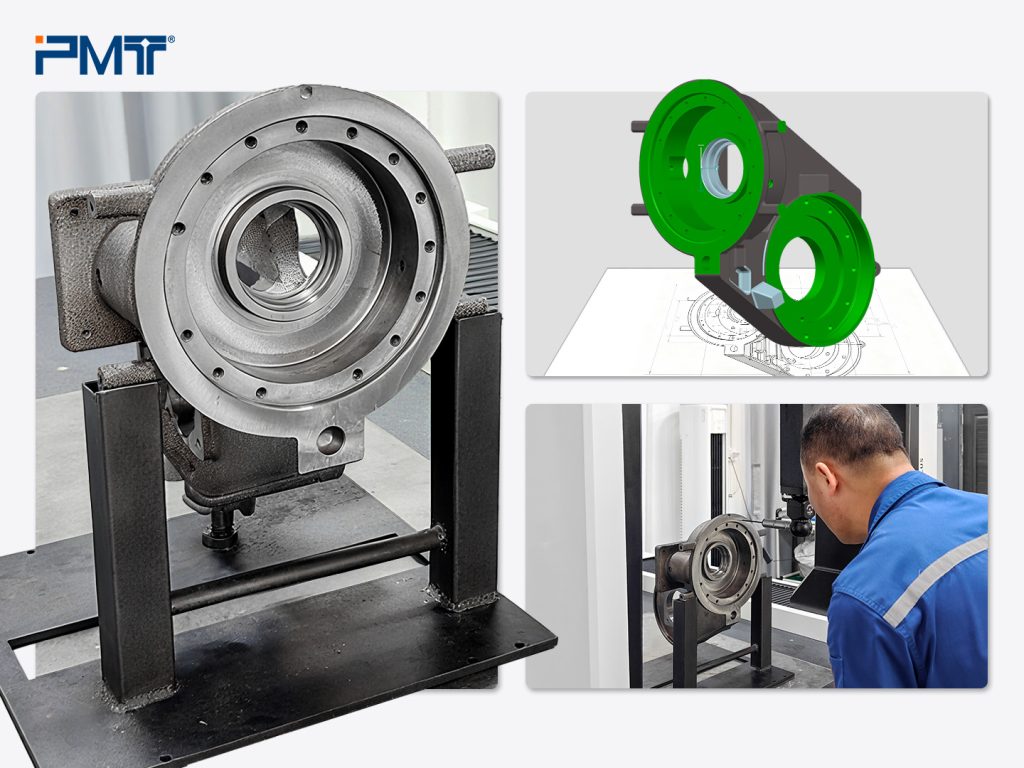

The Solution in Action: Measuring the Robot’s Second-Axis Turntable

Using the FUTURE PLUS 1587, Chengxin engineers conducted a complete inspection of the turntable’s geometric features. Key dimensions such as flatness, perpendicularity, concentricity, and distance between holes were measured with micron-level precision.

The setup included:

- Hardware: FUTURE PLUS 1587 (800 × 1500 × 700 mm measuring range)

- Software: Metrolog X4 + PMT Inspect

- Control System: Renishaw UCC S3 Kit

- Probe System: Renishaw PH10M with SP25 scanning probe

The machine’s flexible probe combinations allowed the team to measure deep holes and complex surfaces that were previously difficult to reach. With automatic scanning and software-based evaluation, Chengxin obtained a complete data map of the part’s accuracy.

Results: Data-Driven Quality and Process Optimization

Once the PMT CMM was fully integrated into Chengxin’s inspection process, the benefits were immediate. The precise measurement data helped engineers identify the root cause of assembly misalignment, optimize machining parameters, and improve process stability.

Beyond the robot turntable, the FUTURE PLUS 1587 has since been applied to other projects, such as MTU main bearing caps, marine cylinder heads, and connecting rods. The consistent accuracy and traceability have strengthened Chengxin’s overall quality control and production efficiency.

Building the Future of Precision Manufacturing

The collaboration between Chengxin Machinery and PMT represents more than a single equipment upgrade—it’s a shift toward data-driven, intelligent manufacturing. With PMT’s advanced CMM technology, Chengxin continues to set higher standards for precision, reliability, and innovation in the machinery industry.

PMT is committed to empowering manufacturers worldwide with high-precision metrology solutions.

Whether you’re optimizing machining processes or ensuring product consistency, PMT helps you measure with confidence and manufacture with precision.

Learn more about PMT’s CMM solutions and discover how we can help your business achieve smarter, more reliable production.