In the power equipment manufacturing sector, engines play a role similar to the human heart. Their dimensional accuracy and structural integrity directly affect safety, performance, and long-term reliability. During operation, engines are often exposed to high temperature, high pressure, and continuous mechanical load. Under such conditions, even small dimensional deviations—whether in hole position, coaxiality, or surface flatness—can lead to efficiency loss or premature failure.

As a result, engine inspection has gradually moved beyond basic dimensional checks toward more comprehensive and precise quality control. However, traditional measurement methods often struggle to balance accuracy, efficiency, and on-site adaptability. Against this backdrop, portable measuring arms, also known as portable CMMs, are increasingly adopted in engine manufacturing environments to support flexible, reliable, and real-time inspection.

Core Challenges: Limitations of Traditional Engine Inspection Methods

To better understand the value of portable measurement, it is first necessary to look at the limitations of conventional inspection approaches. In many factories, handheld tools such as calipers and micrometers are still used for parts with relatively low accuracy requirements. While these tools are easy to operate, they rely heavily on operator experience and are difficult to standardize across multiple inspectors. More importantly, they cannot fully capture three-dimensional geometric features.

On the other hand, fixed coordinate measuring machines (CMMs) offer high accuracy but require parts to be transported to temperature-controlled inspection rooms. For large or heavy engine components, this process is time-consuming and labor-intensive. In addition, repeated lifting and repositioning may introduce new risks and delays into the production flow.

Because of these constraints, traditional inspection methods often struggle to meet the evolving needs of modern engine manufacturing. In contrast, portable CMM solutions provide a practical alternative by bringing precision measurement directly to the production site.

Why Portable Measuring Arms Fit Engine Inspection Needs

At this point, portable measuring arms demonstrate clear advantages in engine quality inspection. With lightweight structures, flexible articulation, and wireless operation, they can be deployed next to production lines or inside confined spaces without special foundations or environmental control.

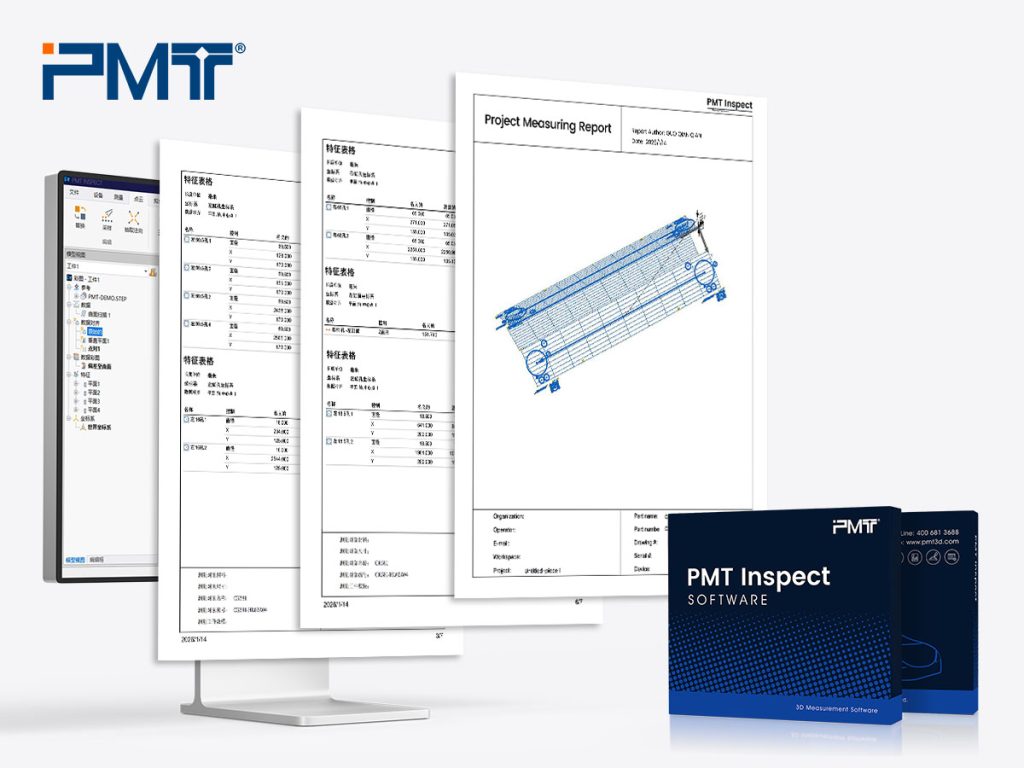

PMT portable measuring arms combine stable measurement accuracy with flexible installation, enabling inspectors to perform on-site measurement without moving large engine components. Supported by PMT INSPECT measurement software, inspection tasks can be standardized, repeatable, and traceable, which helps improve both efficiency and data reliability.

More importantly, portable measuring arms adapt well to the diverse inspection requirements found across different engine types and industries.

Section 3: Typical Engine Inspection Applications

Marine Diesel Engine Compartment Inspection

In the marine industry, diesel engines are usually large in size and difficult to relocate. Moving such components to a fixed CMM is often impractical. In response, PMT portable measuring arms offer a mobile inspection solution that allows measurements to be performed directly inside the engine compartment.

Thanks to a lightweight design and built-in Wi-Fi module, PMT portable CMMs can operate without external cables. Under fully charged conditions, they support long inspection cycles, ensuring continuity during multi-feature and multi-angle measurement tasks. Inspectors can efficiently evaluate cylinder bore diameters, distances, and other tolerance-related features without interrupting the workflow.

In addition, PMT INSPECT software supports batch inspection functions, allowing the same measurement program to be applied to multiple engines of the same model. This significantly improves inspection efficiency and consistency in marine engine production.

Automotive Engine Block Inspection

Moving from marine engines to automotive manufacturing, engine blocks form the structural foundation of the engine system. Key features such as bearing bores, hole positions, flatness of sealing surfaces, and distances between locating pins directly influence engine assembly and long-term stability.

In this scenario, portable measuring arms can be placed next to the production line to perform rapid inspections. After collecting dimensional data, inspectors can compare results with design tolerances in real time. This immediate feedback helps identify deviations early and supports timely process adjustment, improving the responsiveness of quality control in automotive engine production.

Agricultural Machinery Engine Housing Inspection

In agricultural equipment such as tractors, engine housings are often heavy and complex, with deep internal holes that are difficult to access using conventional tools. Portable measuring arms address this challenge by enabling in-place measurement without dismantling the component.

With flexible joints and optional extension probes, PMT portable CMMs can reach deep into engine cavities to accurately measure hole diameters, roundness, and positional relationships relative to mounting surfaces. This capability allows inspectors to complete comprehensive checks even in confined internal structures.

New Energy and Hybrid Engine Cover Measurement

In new energy and hybrid power systems, engine covers play a critical role in installation accuracy and sealing performance. PMT portable measuring arms equipped with both tactile probing and scanning capabilities support full-size inspection of these components.

Using a touch probe, inspectors can verify locating pins and critical interface dimensions. When combined with a scanning head, complex surfaces and contours can be captured efficiently for further analysis. This integrated approach supports both dimensional verification and design optimization, making portable measuring arms a valuable tool in new energy engine inspection.

Section 4: Software Integration and Process Standardization with PMT INSPECT

While hardware flexibility is essential for engine inspection, software capability ultimately determines whether measurement results can be effectively transformed into production value. In this regard, PMT portable measuring arms are deeply integrated with PMT INSPECT 3D measurement software, forming a unified platform that supports standardized inspection workflows and data-driven quality management.

First, PMT INSPECT enables inspectors to build repeatable measurement programs based on part drawings and CAD models. Once established, these programs can be reused across different shifts, operators, or production batches. This significantly reduces dependence on individual experience and ensures that inspection methods and evaluation criteria remain consistent throughout the production lifecycle.

Second, during the inspection process, measurement results are displayed in real time, allowing deviations to be identified immediately. This real-time feedback supports faster decision-making on the shop floor, helping engineers adjust machining parameters or assembly processes before issues propagate further downstream.

In addition, PMT INSPECT supports visual reports and statistical analysis, including SPC-related functions. By analyzing dimensional trends over time, manufacturers gain better insight into process stability and quality risks. As a result, inspection shifts from a passive verification step to an active tool for continuous process improvement.

Section 5: From On-Site Measurement to Long-Term Quality Value

Beyond individual inspection tasks, the broader value of portable measuring arms lies in how they reshape quality control strategies. By moving precision measurement from the laboratory to the production site, PMT portable CMMs help manufacturers shorten feedback loops and reduce non-value-added time.

For engine manufacturers dealing with large components, frequent design changes, or multiple product variants, this flexibility is especially critical. A single portable measuring arm can support multiple workstations, production lines, or even external suppliers, maximizing equipment utilization while minimizing infrastructure investment.

At the same time, the combination of tactile probing and optional scanning expands application boundaries—from basic dimensional verification to complex surface analysis and reverse engineering. This makes PMT portable measuring arms suitable not only for routine inspection, but also for prototype validation, process optimization, and quality troubleshooting.

Conclusion: Redefining Engine Inspection with PMT Portable Measuring Arms

In today’s engine manufacturing environment, quality inspection must be accurate, efficient, and adaptable. PMT portable measuring arms meet these requirements by combining stable measurement precision, flexible deployment, and seamless software integration.

Across automotive, agricultural machinery, marine, and new energy industries, PMT portable CMM solutions support key engine inspection tasks—from deep-hole measurement and coaxiality evaluation to large-structure verification and complex surface analysis. By enabling on-site measurement and standardized workflows, they help manufacturers improve responsiveness, reduce rework, and enhance overall product reliability.

If you are looking to upgrade your engine inspection process with a flexible and reliable portable measuring arm solution, PMT is ready to support you.

Contact PMT today to learn how our portable CMM systems and PMT INSPECT software can help you build a more efficient, data-driven quality inspection workflow.