Indispensable and efficient tool in the field of tooling inspection and adjustment.

Portable measuring arm, also commonly known as portable coordinate measuring machine(CMM), is a high-precision device with similar structure to the multi-axis industrial robot. Its portable and flexible design is suitable for conducting on-site inspection anytime and anywhere. Through its fixed arm length and real-time angle changes, the measuring arm can calculate exactly the coordinate values of the probe at any given point and acquire the parameters such as GD&T and 3D coordinate values of workpieces. It’s worth noting that the portable measuring arm offers key advantages, such as boosting production efficiency and ensuring high accuracy. These benefits significantly contribute to higher yield rates and enhanced quality control.

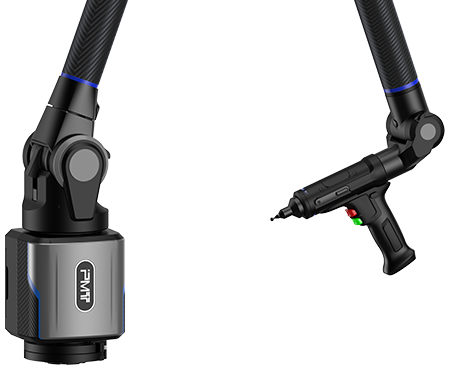

As a revolutionary benchmark for portable CMMs, PMT measuring arm offers the leading 3D measurement solution.With PMT’s high-accurate encoders and carbon fiber material, the PMT portable CMM with ergonomic design is super durable and reliable. Fundamentally, the core advantage of the PMT's portable cmm lies in its efficient measurement capabilities, its lightweight design facilitates true single-handed operation.

With its world-class repeatability accuracy and high measurement efficiency, PMT ARM has demonstrated strong competitiveness and has emerged as a preferred solution for intelligent measurement applications across various industries.

Perfect Precision and Stability

The PMT GAMMA 7-Axis measuring arm equipped with an 8-Axis rotary worktable expands the measuring volume and the high-precision blue light scanner offers quick and accurate scanning results.

The GAMMA laser scanner enables fast and accurate inspection to obtain the most precise measurements.

Best-in-class performance

With internal counterbalance system and equi-arm design, it is the most suitable measuring arm for on-site measurement.

Designed for educational institutions, it aims at providing the most economical and effective teaching solutions.

Equipped with a blue light scanner, it offers extensive measurement ranges, highlighting the concept and application of the measurement technology in different scenarios.